5 HMI Technology Trends

Whether it’s part of a process to pave the way for an Industrial Internet of Things (IIoT) initiative or simply to provide more accessible insight into operational capabilities, the role of the human machine interface (HMI) has clearly moved front and center for many companies. In reaction to increasing manufacturer interest for more versatile HMI capabilities, HMI technology suppliers are actively bridging the gaps in HMI technology that long kept it affixed to the machine(s) it monitored. To gather insight into some of the key advances that have been changing HMI technology over the past few years, I spoke with Jeff Thornton, product manager at Red Lion Controls. He pointed to five key facets of HMI technology that are changing the common perceptions of HMI. Granted, the technologies that Thornton discussed with me are specific to Red Lion Controls‘ products, but they provide important insights into the direction HMI technology is headed.

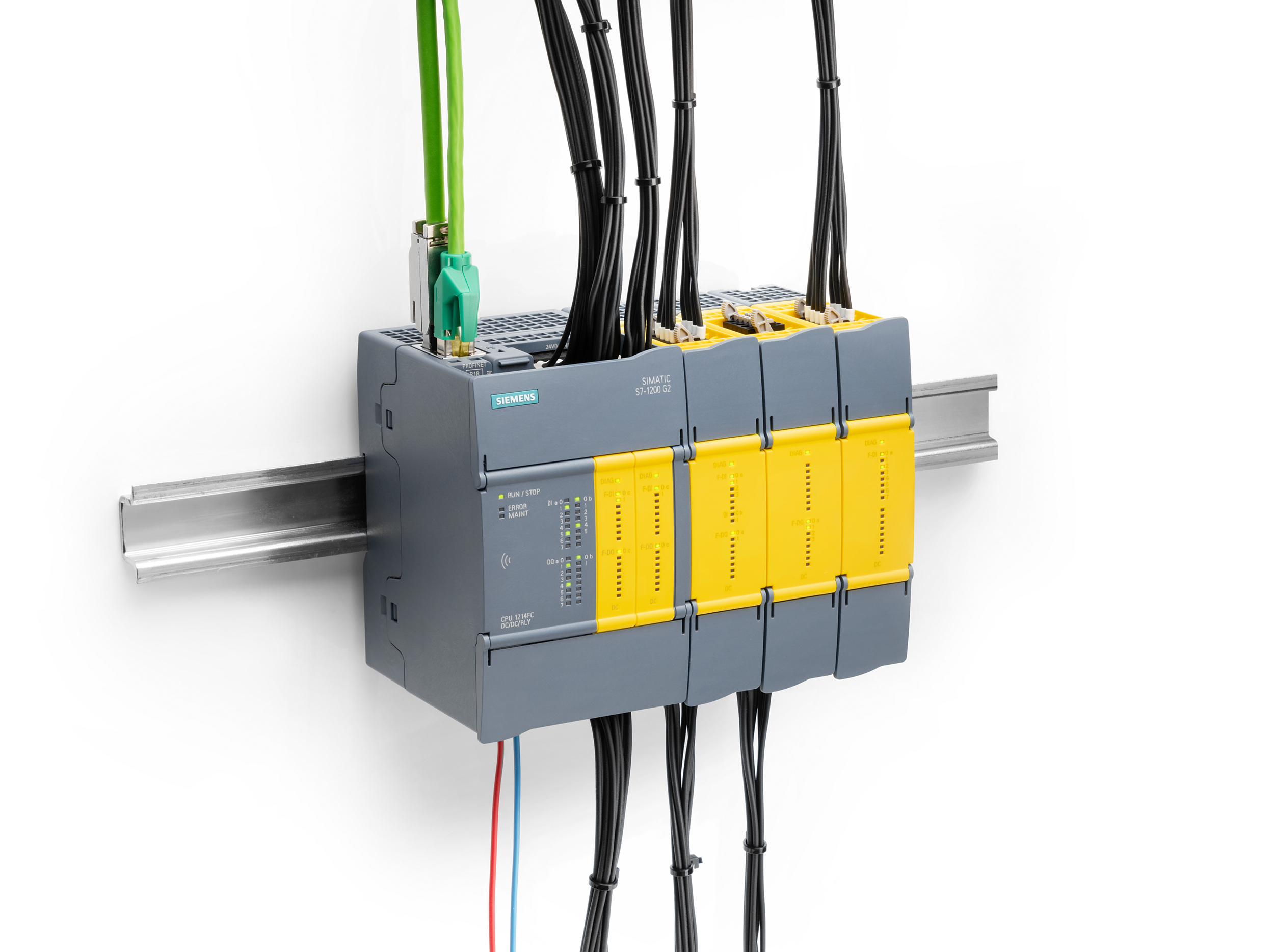

The first thing Thornton pointed out in our discussion of modern HMI technology was protocol conversion. Red Lion’s Graphite HMIs, for example, can be set up as „the gateway to exchange data between all connected devices“, he says. „Graphite HMIs can convert between 13 protocols simultaneously from a list of more than 300 drivers to integrate disparate devices like PLCs, drives, barcode readers and panel meters.“ The ability to manage these complex multi-vendor environments via programming software is the second technology advance Thornton highlighted. „Red Lion realized customers were spending too much time setting up HMIs, so we designed plug-in modules for our Graphite HMIs“, he said. „These modules minimize development and commissioning time over traditional systems that use an HMI paired with separate I/O, PLCs and other controllers.“ Web serving and data logging are two big trends in the HMI space – and the third major HMI technology advance noted by Thornton. He said that Graphite HMIs are „the only rugged HMI that web-enables any device for remote operation across a LAN or the Internet. Users can remotely monitor and control applications via PCs, tablets or smartphones to streamline operations. When problems occur, SMS text messages and email alerts can be automatically sent to maintenance teams for proactive problem resolution.“ When asked about the security concerns surrounding remote access to industrial systems, Thornton pointed out that remote access to Graphite can be set up as disabled (no access), view only, or full control of the HMI. „Based on who is logging into the HMI, the software can dictate what level of permissions will be granted,“ he says. The proprietary operating system used to run Graphite HMIs are a factor that Thornton says protects Graphite HMIs from many of the security threats affecting HMIs using a more common operating system. The ruggedness of Graphite HMIs is the fourth HMI advance Thornton notes about modern HMI technologies. „For some industries, like oil and gas, alternative energy and water/wastewater, an HMI needs to stand up to harsh conditions“, he says. „It used to be tough to take an HMI out into oil fields or have it withstand very hot or cold temperatures. But with the use of cast-aluminum metal housing, such as on the Graphite HMIs, these devices can now withstand shock and vibrations and extreme temperatures between -20 to 60°C.“ With the ability to now take your HMI practically anywhere with you, how the device collects, processes and presents data continuously for proactive monitoring and control becomes ever more important – and the fifth modern HMI technology pointed out by Thornton. „The ability to collect, store and display data for real-time analysis provides valuable insights into processes that enable operators to analyze output levels, detect valve issues, or identify temperature extremes“, he says. „By logging real-time performance data, including productivity and output comparisons, organizations can easily implement process improvements or quickly pinpoint and address bottlenecks or chokepoints.“